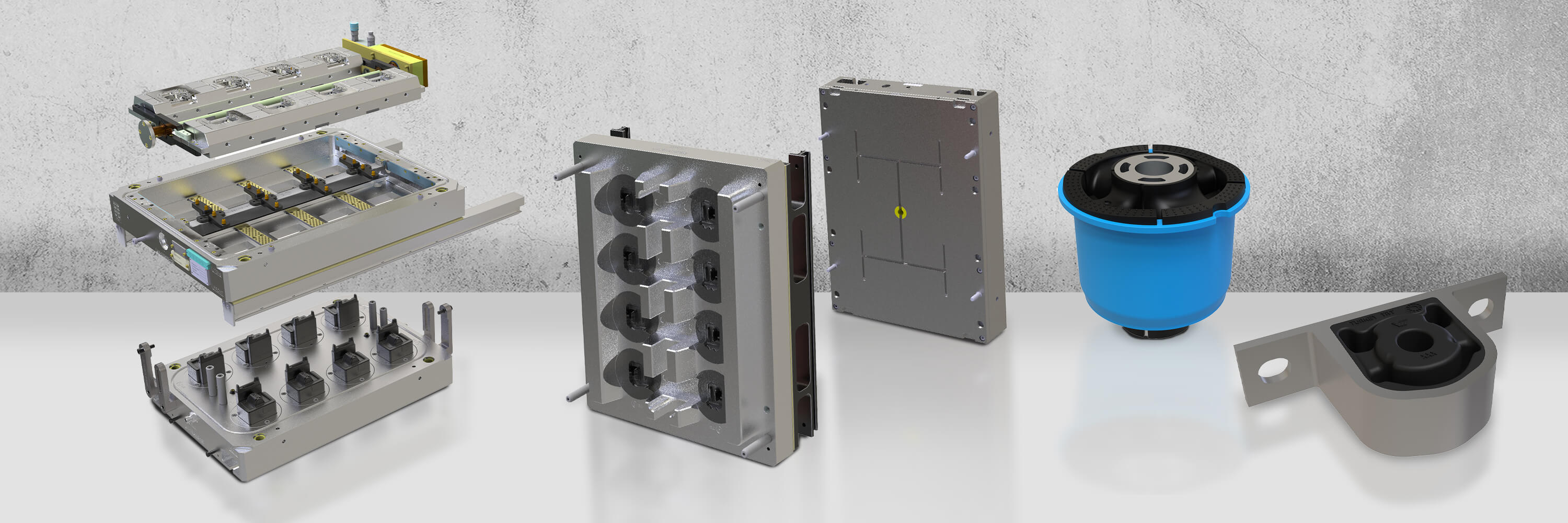

Rubber Injection Mold Manufacturing

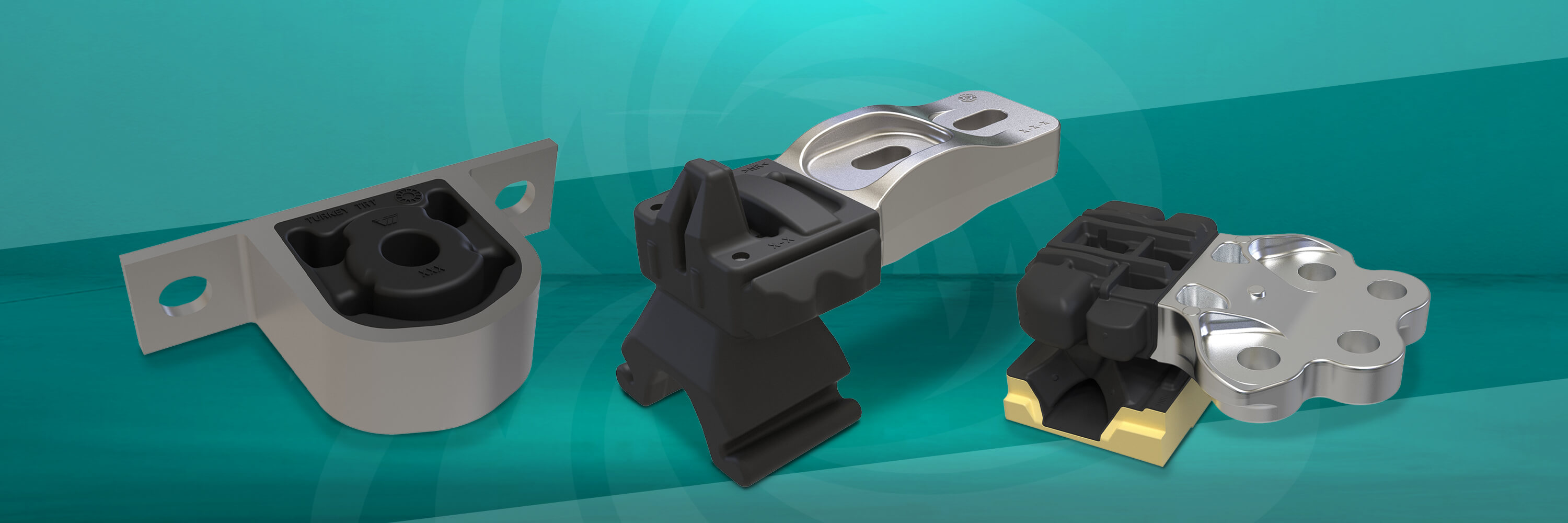

The process involves injecting rubber in its uncured, dough-like state into precision-engineered metal molds. This injection molding technique is optimized for high-volume manufacturing and is extensively utilized in sectors such as automotive, electronics, and medical devices. During the process, the rubber compound is heated within the injection molding machine until it reaches a flowable, viscous state, then injected under pressure into the mold cavity. Inside the mold, the material undergoes cooling and vulcanization, solidifying into the final part geometry. This method enables the production of components with tight dimensional tolerances and intricate designs, while also providing the advantages of rapid cycle times and cost-effective mass production.